Each RNG Unit generates approx. 8,000 cu. metres of clean gas per day rated at 1,000+ BTUs per cu. Metre

Waste to Energy

Trillium RNG Technology

(RNG = Renewable Natural Gas)

Full Size Working Prototype

Capable of Processing Waste (Garbage), Wood and other Biomass!

Brief Synopses of the Trillium RNG Technology

(RNG = Renewable Natural Gas)

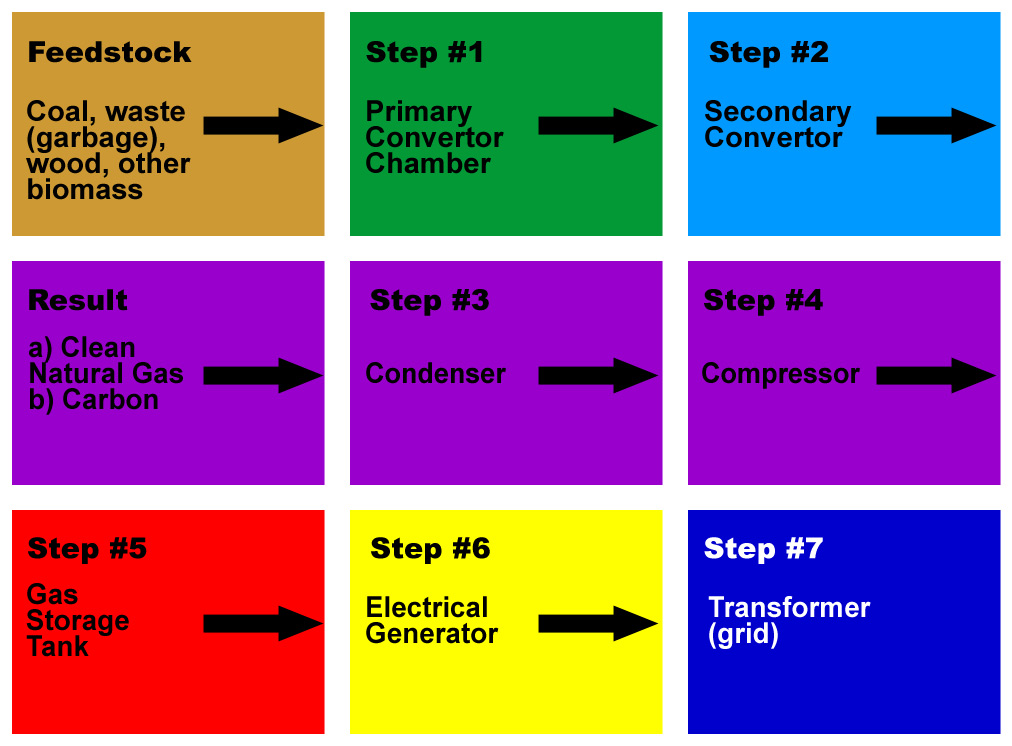

Simply Stated: Feedstock is processed through the RNG Technology and turned into electrical energy with NO emissions into the atmosphere!

Note: By adding a 'pre-processor' before Step #1 [which removes moisture and shreds the Feedstock, i.e. Wood, Waste (garbage)

& other Biomass] the same equipment can also be used to turn this alternative feedstock into electrical energy with virtually the same process.

Following is a very simplistic explanation of how the system operates along with the potential electrical energy output of only one unit!

- Primary Convertor Chamber

- Secondary Convertor Chamber

- Clean Natural Gas and Carbon

- Condensor

- Compressor Tank

- Gas Storage

- Electrical Transformer

-

-

Therefore each RNG Unit generates 8 Million BTUs per unit per day! (8,000 cu. metres per day x 1,000 BTUs per cu. metre)

-

Consequently, each RNG Unit yields about 1.5 MW of electrical energy per day. (possibly more, dependent on feed stock)

- The start of the entire RNG process begins in the primary converter chamber that, in an oxygen free atmosphere, rapidly heats the incoming feedstock extracting various component molecules while sequestering noxious materials found in the carbon as well as producing a high BTU organic gas.

- The secondary converter chamber receives these component molecules from the primary converter chamber and, in an oxygen-free atmosphere, cleanses the gas captured in the primary converter chamber while also emitting carbon. The residue of this process (made up of resin and tars) goes back into the primary converter chamber and is used as fuel thereby making the RNG Unit self-sustaining.

- Result Clean Natural Gas and Carbon

-

Condenser - The gas outputs from the Primary and Secondary Converter Chambers are processed through the condenser as a final cleansing of the organic gas, removing any minuscule tar particles and impurities. During this process tars are converted from a gas to liquid form and utilized in a small 'gasifier', creating an additional fuel source to heat the primary converting chamber.

-

Carbon - The carbon converted from the primary conversion chamber cools in the carbon holding tank. This carbon, because it has no nitrogen in it, can be used (by EU definition) as a soil enhancer. The RNG Unit can produce roughly 8 tons of carbon per day.

-

- The compressor, as per its title, simply compresses the clean organic gas.

- The gas storage tank stores the compressed organic gas until it is drawn upon for use by the generator.

- The electrical generator (presently a set of 3520 Cat Generators) generates electricity.

- The transformer transforms the electricity created from the generator to the site specific voltage for substation and grid requirements.

Note: There is absolutely no combustion in the RNG system as everything is done in an oxygen-free environment.

Note: In certain circumstances, Alternative (non-repayable) Funding is available to underwrite the entire cost of a turnkey RNG operation for a fairly substantial number of the RNG units. Not only can the cost of the purchase and installation of a turnkey RNG operation be underwritten but the use of this technology will also considerably diminish the cost of electricity, cut pollutants to zero everywhere the RNG Unit is used but also produce a significant amount of Revenue. This funding comes through earned income (usually) from private sources (sometimes public) so it is not a loan and never has to be repaid. If you are in need of funding for this type of endeavour please contact somone listed in this information.

Trillium Waste Conversion System - Approx. BUILDING FLOW Time-Frame

Feedstock [wood, waste (garbage), other biomass and coal] provided by Trillium is processed using a patented advanced

thermolysis technology with zero emissions into the atmosphere. Resultant renewable natural gas is converted without

scrubbing or cleaning to produce electrical energy for the grid.

Following are the steps that are in the process of being taken to complete the Trillium Waste Conversion System.

Note: The entire technology has been validated via independent engineering firms and government testing. Also, on-site unit

operation, including the production of electricity, has already been ongoing for a sustained period of time.

Step #1 Three to four representative feedstock samples need to be taken and analysed which will more accurately determine

the outputs. The analysis of the feedstock (waste composition) will determine the size of the Vortex Shredder that will

be needed for the Front End (Pre-processor) of the unit. When this analyses is completed the results are sent to the lab in North Carolina.

2 Weeks

Step #2 Several large metal buildings will be built in/for Sri Lanka in which the various proponents

(Front End, Middle, Back End) of the total unit need to be placed. The buildings should have a flat (preferably concrete)

floor as well as an appropriate electrical service.

4 Weeks

Step #3 Most of the Middle portion of the unit has already been built but several newer replacement components need to be purchased, installed and tested.

10 Weeks

Step #4 Prior to shipping to Sri Lanka, new Front End and Back End units need to be ordered, attached and tested.

from date of contract. (Step #4 will probably overlap other steps).

4 Weeks

Step $5 After the complete unit is tested it will be disassembled and shipped to Sri Lanka where it will be reassembled and retested.

The unit should then be functional and, at the latest, producing electricity near the end of July, 2016. All permits, etc. need to be ready!

10 Weeks

Prior to shipping, each unit will be built, fully assembled, tested to insure performance to specification, disassembled, shipped,

reassembled and made ready to produce electricity when attached to the grid. Simultaneously built units: 3 - 4 months each batch.